Epilog - Cleaning the X-Axis Linear Encoder

Issue:

If you are seeing wavy engraving, or the engraving seems to be drifting across the page, you probably have a dirty linear encoder. Cleaning is a quick process that we will explain below.

Solution:

Before you begin the steps for cleaning your x-axis linear encoder strip, you'll need a few tools:

- Phillips head screwdriver

- Distilled water

- Cotton swabs

- Can of compressed air (optional)

Step 1:

There are seven screws that attach the x-axis linear guide cover: two on the front side and five on the back. Unscrew each of the screws until each one is loose enough to remove the linear guide cover

You will not need to remove all of the screws to remove the cover completely.

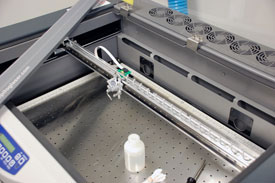

The linear encoder strip is the clear plastic strip that runs along the width of the x-axis beam pictured above.

Step 2:

Using the cotton swab dipped in distilled water, wipe the cotton swab along the front and back side of the linear encoder strip to remove any smoke or dust debris that might have collected on the strip.

Once you've finished wiping down each side of the encoder strip, go back with a dry cotton swab and wipe away any moisture that might have been left behind.

Step 3:

Now place the linear guide cover back onto the x-axis beam using the partially unscrewed screws as a guide. Tighten the front screws first, followed by the back screws last.

Conclusion:

And now you're finished! How often you'll need to clean your linear encoder strip will depend primarily on what type of materials you are engraving and cutting.

Related Articles

17000 (Maker Edge Pro) - CO2 Laser Alignment

Introduction In this article we’ll walk you through aligning the laser on the Epilog Fusion Edge & Fusion Pro. During this procedure, all persons present in the room must be equipped with eye protection, such as safety glasses, eyeglasses or goggles. ...17000 (Maker Edge Pro) - X-Axis Belt Tensioning Guide

Instructions on tensioning the X-Axis belt on a 17000 Edge, Maker, Pro, or 16000 Pro 48 200 Watt. Overview This document and video provide instructions on utilizing the X-Axis belt tensioning tool. The tool assesses the belt's tightness, allowing us ...Epilog - Mini, Helix Laser Alignment

CO2 laser alignment should be checked periodically to ensure the engraver is performing optimally. Download the Attached PDF for Detailed Instructions. Complete this procedure if any of the following behaviors are observed: Laser power appears weak ...Preventative Maintenance Schedule – Epilog Fusion Edge & Pro 17000 Series

This guide outlines the recommended preventative maintenance (PM) schedule for the Epilog Fusion Edge & Pro 17000 Series laser systems. Performing these tasks regularly ensures optimal performance, reduces fire hazards, and helps extend the life of ...Epilog - Zing 24 Laser Alignment

CO2 laser alignment should be checked periodically to ensure the engraver is performing optimally. Download the Attached PDF for Detailed Instructions. Complete this procedure if any of the following behaviors are observed: Laser power appears weak ...