Epilog Fusion Maker and Edge 12 – Pre-Install Checklist

Before scheduling installation or training for your Epilog Fusion Maker 12 or Epilog Fusion Edger 12 laser system, please verify that all utilities, workstation setup, and site conditions meet the requirements listed below.

✅ Power Requirements

- ✔️ Voltage: 120V AC, 60 Hz

- ✔️ Dedicated 15A grounded outlet

- ✔️ Outlet should be within 6 ft (1.83 m) of the machine

- ✔️ Do not use extension cords or power strips—plug directly into wall outlet

✅ Workstation & Software Requirements

- ✔️ Windows 10 or newer computer required

- ✔️ Compatible vector software: CorelDRAW or Adobe Illustrator

- ✔️ Download and install Epilog Dashboard software here

- ✔️ Administrative access is required to install software and drivers

- ✔️ Coordinate with your school's IT department to ensure they are available during setup

✅ Network Connection Requirements

- ✔️ Ethernet connection is strongly recommended in school environments

- ✔️ Wi-Fi is not recommended for reliability or security reasons

- ✔️ Ensure a nearby active network drop or switch port

- ✔️ IT support should be available for any networking/firewall changes

✅ Ventilation Requirements

- Choose one of the following options:

- Option 1: External Exhaust

- ✔️ 4" diameter hose connection required

- ✔️ Minimum 350 CFM

- ✔️ Route to an exterior vent with minimal bends for efficient airflow

- ✔️ 4" diameter hose connection required

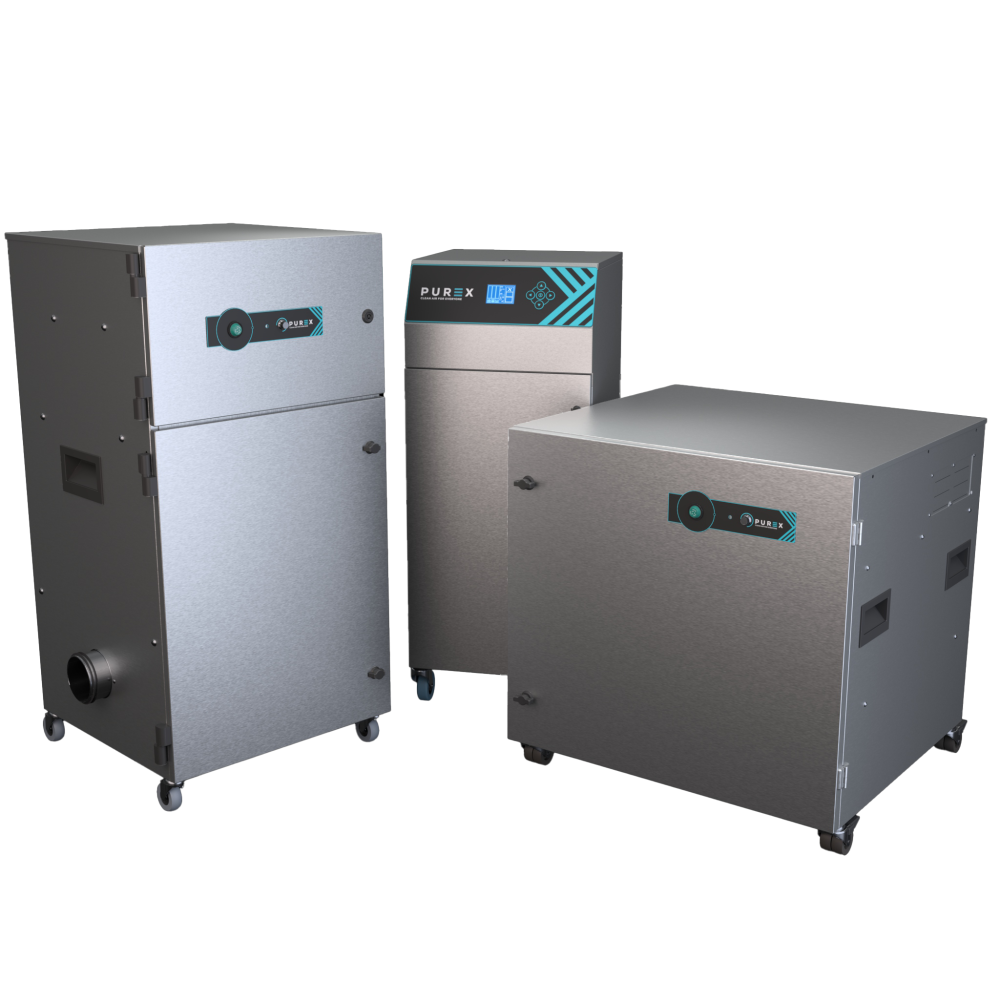

- Option 2: Filtration System

- ✔️ Connect to a compatible fume extraction system (sold separately)

- ✔️ Ensure filters are properly installed and maintained

✅ Air Assist Requirements

- Choose one of the following options:

- Option 1: Included Air Assist Pump

- ✔️ Use the provided air pump included with the system

- ✔️ Connect directly to the air inlet port on the machine

- Option 2: External Compressed Air

- ✔️ Clean, dry compressed air only

- ✔️ Maximum pressure: 20 PSI

- ✔️ Must be regulated and moisture-free

✅ Other Site Considerations

- ✔️ Machine weight: Approx. 150 lbs

- ✔️ Requires a sturdy table with minimum dimensions of 40" x 27"

- ✔️ Minimum clearance:

- Rear: 6 inches

- Sides: 12 inches

- Front: Allow full lid access

- ✔️ Operating temperature: 60–80°F (16–27°C)

- ✔️ Humidity: 30–70% (non-condensing)

- ✔️ Avoid areas with heavy dust, EMI, or vibration

Once all items in this checklist are complete, please contact our support team to confirm and schedule installation and training.

Related Articles

Epilog Fusion Maker 36 & Edge 36 – Pre-Install Checklist

Before scheduling installation or training for your Epilog Fusion Maker 36 or Epilog Fusion Edge 36 laser system, please verify that all utilities, workstation setup, and site conditions meet the requirements listed below. ✅ Power Requirements Fusion ...Epilog Fusion Maker and Edge 24 – Pre-Install Checklist

✅ Power Requirements ✔️ Voltage: 120V AC, 60 Hz ✔️ Dedicated 15A grounded outlet ✔️ Outlet should be within 6 ft (1.83 m) of the machine ✔️ Do not use extension cords or power strips—plug directly into wall outlet ✅ Workstation & Software ...17000 (Maker Edge Pro) - CO2 Laser Alignment

Introduction In this article we’ll walk you through aligning the laser on the Epilog Fusion Edge & Fusion Pro. During this procedure, all persons present in the room must be equipped with eye protection, such as safety glasses, eyeglasses or goggles. ...17000 (Maker Edge Pro) - CO2 Laser No Outuput Checklist

This document is designed to help determine if you need to replace your laser tube. Overview These items should be checked before replacing a CO2 laser tube with no output. If the laser has been inactive for more than one (1) month, follow the ...17000 (Maker Edge Pro) - CO2 Laser Low Output Checklist

Overview Having to continually reduce speed and increase power can indicate low output from the laser. This document will help identify a low output laser tube on a 17000 Maker, Edge, or Pro machine. There is a PDF version of this document on the ...